Starya Mobility Becomes The 1st Indian EV Company To Introduce An Indigenously Built And ARAI Certified Electric Powertrain

Electric vehicles(EV) are on-trend and going to rule the automotive industry in the coming years. The internal combustion(IC) engines and fuel tanks will be replaced by electric powertrain and battery respectively. The electric powertrain is the most important part of an EV that generates and delivers power to the vehicle required to move on the road surface.

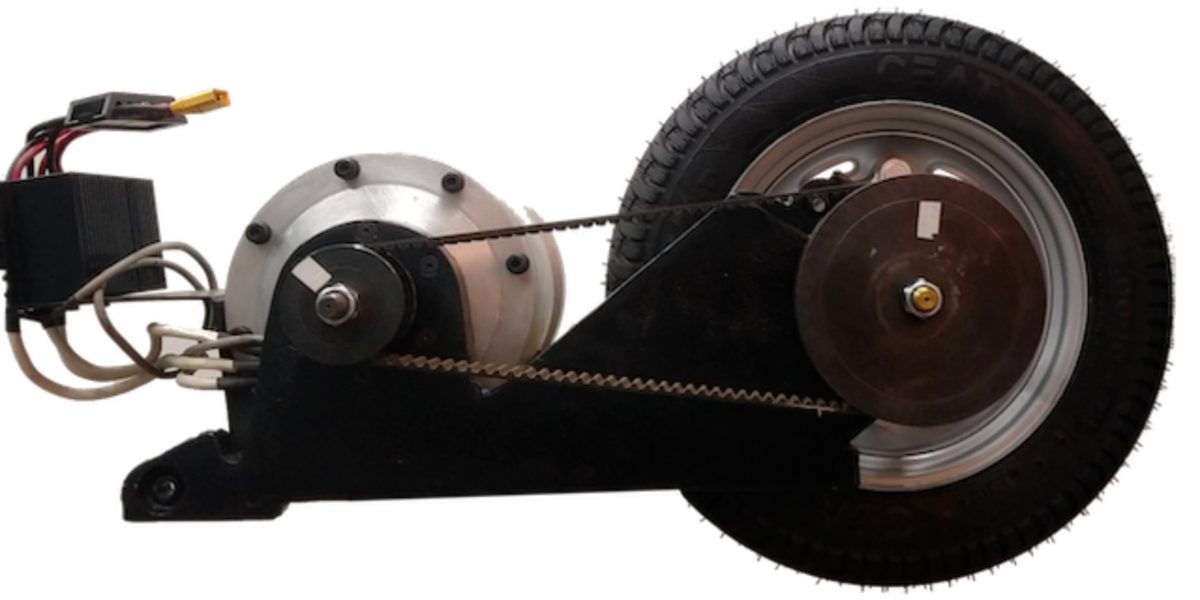

The Bengaluru-based retrofitting scooter company ‘Starya Mobility’ was working to launch a cost-effective electric powertrain for the last 4 years and has successfully engineered a 5.5kw patented PMSM Motor & Controller that will convert petrol scooter to pure electric. Currently, the company aims to convert existing petrol scooters to electric, and in the future, it will also help convert light load conventional vehicles into electric.

Starya Mobility is the very first company in India to introduce an indigenously built & ARAI approved electric powertrain:

The company strongly believes that this ARAI approved electric powertrain will be a game-changer in the EV industry by directly impacting the electric vehicle(EV) ecosystem. Indigenously developed and tested to match the Indian roads and sustain the climatic conditions, it is unique of its kind. Apart from selling its patented electric powertrain and offering RTO-approved complete retrofitting service the company is also open to B2B collaborations for its motor and controller supply to boost the EV industry growth worldwide in order to fulfill the industry demands.

“We are the front runner in electric powertrain developed indigenously, till today no other EV company or retrofitting company has launch EV vehicle or powertrain developed purely on indigenous technology and material. They either import the vehicle or the parts and assemble them in India which doesn’t make it cost-effective whereas Starya Mobility’s every component and technology is developed and manufactured in India by networking with local vendors and suppliers, most of them are from the Peenya industrial area of Bengaluru. With the motivation from Atmanirbhar Bharat(self-reliant India), we focused on local vendors and suppliers that helped us to cut costs to develop a cost-effective electric powertrain” co-founder Ravi Kumar said.

The 5.5 KW PMSM motor, 250 A controller unit will be the helping hands for the people looking for adopting EV technology and EV manufacturers who wish to cut down their manufacturing costs. Starya’s electric powertrain is tested and found to be ideal for both two-wheeler and three-wheel vehicles. The robust design and engineering of the ARAI approved powertrain has outperformed on the Indian roads.

For the Indian EV market, the high manufacturing cost is the biggest constraint to selling electric vehicles. Most EV manufacturers are reliant on technology and vehicle parts that are manufactured in foreign countries making it expensive. Starya Mobility is confident that its electric powertrain will solve the problem by making EV technology affordable.

Relief for common people:

The soaring petrol price had irritated common people of India and compelled them to adopt electric scooters but the high selling price resists them to buy a new one. Starya Mobility’s electric powertrain will act as a catalyst for faster adoption of EV technology by helping common people to shift from conventional vehicles to electric. It will convert a low-performing petrol scooter into a powerful electric scooter. A 5.5 KW motor, 250 A controller unit will give a better performance than a 125 cc IC Engine petrol scooter.

The running cost of an electric scooter is one-fourth of the petrol scooter. A typical petrol scooter has a running cost of around Rs. 4 per km at the current petrol price whereas an electric scooter has a running cost of Rs. 0.92 per km. For the middle-class people and daily commuters, electric scooters are going to provide relief. If an electric vehicle runs about 1000 km per month the running cost will be Rs. 920 whereas for the petrol scooter it will be Rs. 4000. The annual running cost of an electric scooter and petrol scooters are Rs. 11,040 and Rs. 48,000 respectively. This shows that the more one travels on an electric scooter, the more is the saving.

The Government of India has already concerned about global warming and future threats of climate change due to the rise in pollution levels caused by the emission of gases by vehicles and industries. The fact that more than 25 Indian cities are on the list of 100 most polluted cities of the world has worried the Government of India forced to take immediate action. Several changes in the policy have been made in order to support the growth of the EV industry and encourage people to use EV technology. A target has been set to make up 30% of electric vehicle share by 2030 on Indian roads but this is not easy because the petrol scooters have been dominating and there is some limitation for electric vehicles that resists the sale of a new electric vehicle. Retrofitting the scooter will be the better solution to achieve the target by converting the existing petrol scooters to electric with the help of a petrol to electric conversion kit.

Why converting a petrol scooter to electric is better than buying a new one?

Manufacturing a new vehicle will contribute to more pollution due to industrial and transportation activity whereas retrofitting will reduce the pollution compared to the former as converting a petrol scooter to electric doesn’t involve much industrial activity.

Retrofitting is the best option to experiment with the adoption of EV technology. If anyone thinks it takes a longer time to adopt new technology, then retrofitting is a good choice because this can be done at a price between Rs. 35,000 to Rs. 38,000 whereas buying a new electric scooter costs around one lakh.

There are more than 5 crore two-wheelers on Indian roads, if most people buy a new electric scooter then the population of the scooter will rise drastically making traffic more congested. If people go for retrofitting by converting petrol scooters to electric it will be a win-win situation.

Common people cannot afford a brand new electric scooter due to a lack of financial support and their old outdated scooter has very low resale value. In order to make such people accessible to EV technology, Starya Mobility offers a complete petrol scooter to electric conversion facility at an affordable rate of Rs. 35,000 taking care of all RTO formalities. Thus EV technology is accessible with a low initial investment to a common people.

The electric scooter has one-fourth the running cost of a petrol scooter. For middle-class family daily commuters, this will be a huge saving annually. They can utilize these savings for their family’s support, children’s education, home improvement, etc.

Bring the change by utilizing clean energy. Mankind is already worried about the future threat of climate change that will lead to the extinction of species and disturb the chains of the ecosystem. Apart from this Prime Minister Narendra Modi’s vision of Atmanirbhar Bharat(self-reliant India) will get a push that aims to make India economically strong.

Starya Mobility Business Goals:

The company aims to expand its business in 15 plus tier-1 and tier-2 cities in India, these target cities are the ones with a high two-wheeler population. Starya Mobility will open a certified workshop in these cities and the operation may kickstart in the fourth quarter cycle of 2022. In order to achieve its business goal, this startup is raising 50 crore capital to scale up the business in the EV domain. Apart from RTO-approved retrofitting services, the company is open to B2B to supply its ARAI approved electric powertrain in a mass.