Recycling Startup Redwood Materials Is Partnering With Proterra To Supply EV battery Materials Sustainably

A growing number of companies have emerged over the last few years determined to reduce waste in the electric vehicle battery market. Chief among these is recycling firm Redwood Materials, which has quickly expanded since its launch in 2017 by Tesla co-founder JB Straubel to become the largest lithium-ion battery recycler in North America. Now the firm is teaming up with electric commercial vehicle manufacturer Proterra in a deal that may help boost the domestic battery supply chain.

This is the first publicly announced partnership between Redwood and an automaker.

Under the agreement, all Proterra batteries will be sent to Redwood’s facilities for recycling in Carson City, Nevada. The two companies entered the agreement in January, but have been in discussion since last summer, when Proterra reached out to learn more about Redwood’s recycling process. That led to a trip out to Redwood’s facilities in Nevada to see if the recycler could process Proterra battery packs.

“That went really well,” Proterra CTO Dustin Grace said. Grace worked for Straubel for around nine years at Tesla. “We were super excited to see their operation. From there, we started work on our master supply agreement.”

Proterra has sent around 26,000 pounds of battery material to Nevada for recycling since entering the partnership, though this does not represent the pace of future deliveries. Overall, Redwood receives 60 tons per day, or 20,000 tons of batteries per year.

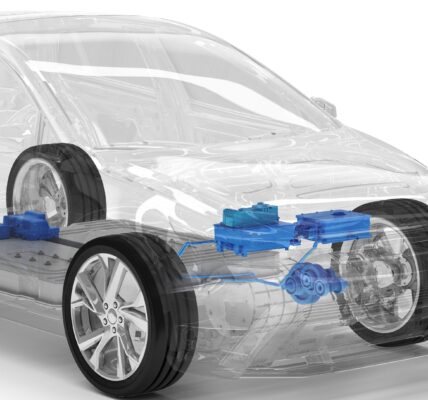

The batteries that power Proterra’s fleets are designed to last the lifespan of the vehicle, but the company offers a battery leasing program that guarantees replacement after six years — which means plenty of useful life will remain in the battery, as much as 80-90% charging capacity. To exploit the remainder of this capacity, Proterra has plans to reuse the batteries in second-life applications — such as in stationary storage systems hooked up to Proterra charging hardware — before they head to Nevada.

“First the grading of the battery will occur at Proterra by our remanufacturing engineering team. If the battery is deemed ready for second-life, it will go into one of those applications; if it’s not, it gets recycled,” Grace said.

Only once all this useful life is exhausted will the batteries be sent to Redwood, where the waste will be reprocessed into valuable raw material. And with the transit EV market poised to reach 50% of all annual sales by 2025, there will be plenty of batteries that will need reprocessing.

The news comes just weeks after Redwood announced it was teaming up with e-bike manufacturer Specialized to recycle its batteries. Redwood already has arrangements to process scrap from Panasonic’s battery cell production at the Nevada Tesla Gigafactory, and with Amazon to recycle EV batteries and other waste. Through these business-to-business partnerships Redwood aims to develop a circular battery supply chain, supplying the raw materials back to the manufacturer. The company also accepts electronics and batteries from everyday consumers, which can be mailed to Redwood via a mailing address posted on its website.

The partnership is a sign that both companies are thinking large-scale and long-term. A spokesperson for Redwood said in a statement that the recycler is focused on “developing the solution for a fully closed-loop recycling for EV batteries.” That means finding truly sustainable, long-term sources of materials like cobalt, lithium and copper to eventually move beyond terrestrial mining. And Straubel has been vocal in the past about his ambition to grow Redwood into one of the world’s largest battery materials companies.

As more battery-grade raw materials become available in the United States, Proterra sees an opportunity to eventually expand into domestic battery-cell manufacturing.

“It’s still early days but we’re trying to set ourselves up for the future state of this market at scale. That’s really the primary benefit of this partnership existing today,” Grace said. “The way we see it, domestic cell production for Proterra is a very, very important part of our roadmap here in the coming years. The idea of generating more battery-grade raw materials on North American soil directly supports the expansion of that battery manufacturing concept within the U.S. So I think this starting now absolutely aids our plans for domestic cell manufacturing in the near future.”