Hutchinson has introduced a noise, vibration, and harshness (NVH) encapsulation product designed to address the acoustic challenges of electric vehicles (EVs).

In a press release, the company said the product is set to equip thousands of electric and hybrid vehicles globally, catering to major original equipment manufacturers (OEMs).

New acoustic and comfort challenges are emerging with the increasing adoption of EVs, including battery electric vehicles (BEVs) and plug-in hybrid electric vehicles (PHEVs).

Unlike traditional combustion engines, the noises from powertrains and electric compressors in EVs are more noticeable, especially during fast charging. This has prompted OEMs and suppliers to seek innovative solutions to mitigate noise pollution while adhering to insulation regulations.

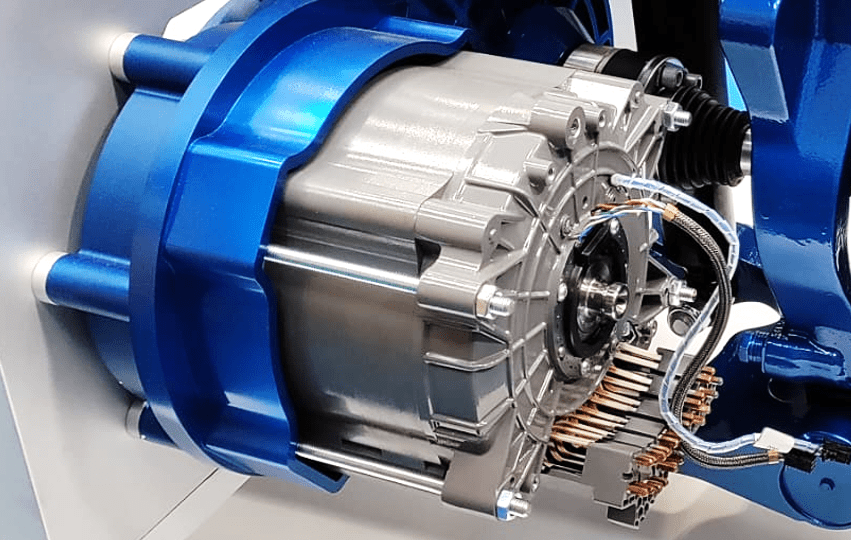

Hutchinson, a provider of sealing and insulation technologies, has developed a multi-layer cover with advanced acoustic properties specifically for electric and hybrid vehicles. This encapsulation product effectively reduces vibration and absorbs high-frequency noises (>1000 Hz) from e-compressors and e-motors. Additionally, it offers optimal thermal insulation, enhancing the performance of e-compressors and cooling systems.

The product is lightweight and is 100% recyclable. Its high-end material expertise ensures the best damping for e-compressors and e-motors when combined with an NVH bracket.

Validated and selected by major international OEMs, Hutchinson’s acoustic cover is expected to equip over 600,000 vehicles annually in Europe and China. To ensure compliance with customer specifications, Hutchinson’s engineering teams conducted extensive tests and validations, including sound absorption, transmission, insertion loss measurement, corrosion resistance, and vibration tests. These tests, supported by the Group’s Research & Innovation Center, also involved numerical modelling for thermal efficiency.

Luis Lafuente, a technical leader at Hutchinson in Vittoria, Spain, explained, “The challenge was to find the best balance between comfort, noise reduction, mass minimisation, industrial feasibility, and durability to ensure that the solutions meet the highest standards of performance and reliability. Through this system, we provide an effective response to environmental challenges and customer expectations.”