GODI, The First Indian Company To Receive BIS Certification To Sell Li-ion Cells In India With Cells Made With In-house Technology For Electric Vehicles

GODI India, has achieved a new milestone by getting the prestigious Bureau of Indian Standards (BIS) certification for its 21700 cylindrical NMC811 lithium-ion cells. As per the BIS requirement, the Godi-designed and made-in-India cells were tested and qualified by TUV, the third-party testing agency. With this, GODI India has become the first Indian company to get this certification for lithium-ion cells in India with their home grown technology.

Commenting on the milestone, Mr. Mahesh Godi, Founder and CEO, GODI India said, “Electric Vehicle penetration in India is expected to become a reality in the near future. As a result, lithium-ion battery based storage solutions will gain prominence and localization of tailor-made cells for Indian conditions will play a vital role, for both automotive and energy storage applications (ESS). As a cell technology player, we would like to be part of this exciting journey. The BIS certificate for our 21700 NMC 811 Li-ion cell is a testament to GODI India’s deep know-how and IP and a significant endorsement of our cell technology. GODI India is innovating in every layer of cell technology. For the first time in the Indian history, NMC811 21700, 3.65V-4.5Ah cylindrical cells were made-in-India & Made-for-India.”

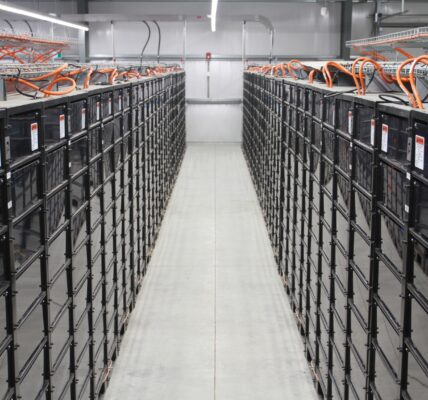

On setting up a production facility, Mr. Mahesh said, “India is expected to be one of the world’s largest and fastest-growing markets for electric vehicles and the customers look for safer and longer-range batteries. It was always our dream to create a technologically advanced lithium-ion cell manufacturing in India. Sensing the need we are setting up our first indigenous giga-factory for lithium-ion cell manufacturing in India by 2024. The new factory will play the role of vitalising the EVs and Stationary Storage industry in India and we will put all our efforts into making sustainable battery cells with a minimal carbon footprint and CO2 emissions.”

GODI India, with a vision to give the best-in-class and safe products to Indian consumers, GODI works with 30+ in-house scientists (Ph.Ds) and experienced engineers to help their customers meet every compliance in India and around the world. The manufacturing facility will have the latest technology in all aspects including carbon-neutral processes and powered by renewables.

Sharing more details about the technology, Mr. Mahesh said, “With our advanced cell technology, we intend to be a leading provider of storage solutions for electric vehicles and energy storage applications in India and will also contribute to reduce India’s dependence on fossil fuels. Our newly developed lithium-ion cell (4.5Ah capacity) with an energy density of 235 Wh/kg has a longer range that meets our customer demands.”

GODI India works closely with research institutes and other government agencies to ensure quality standards in the development and manufacturing of the lithium-ion cells. Compared to many commodity battery kits that are imported, GODI’s cells offer a combination of design sophistication and quality to ensure superior performance and durability. Apart from safety and higher energy density, GODI’s BIS-certified lithium-ion cell gives seven per cent cost savings to the customers. On safety, the company feel it is their duty as a cell manufacturer to provide the right product and never compromise on quality.

About GODI

GODI India is an innovative cell manufacturer focusing on research and development (R&D), and Giga scale Manufacturing (Indigenous Gigafactory) and Recycling of sustainable green energy storage technology. GODI India is a signatory to THE CLIMATE PLEDGE and it is determined to accomplish a zero-carbon footprint by promoting and adopting environmentally friendly and complaisant technologies in the fastest and safest possible way. The company is committed to ethical and humane sourcing of material along with the minimal impact on the environment.